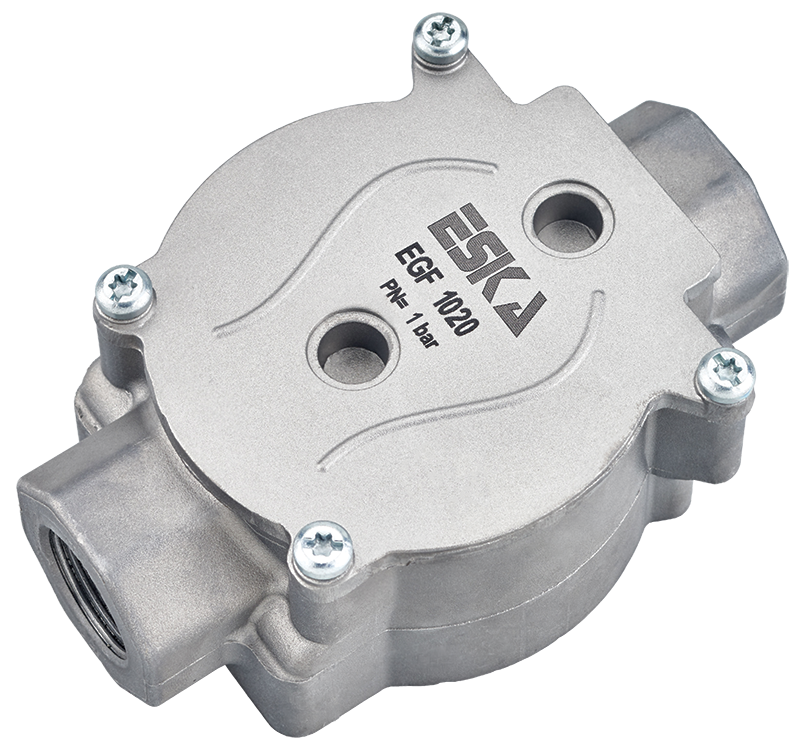

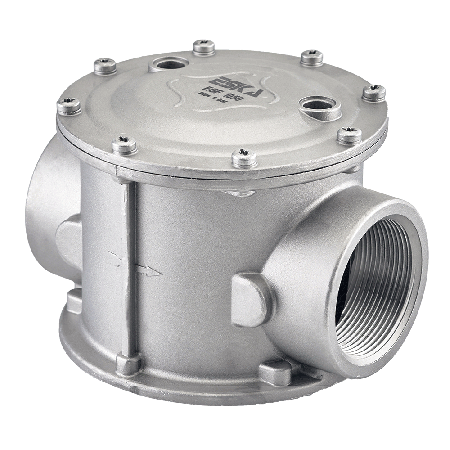

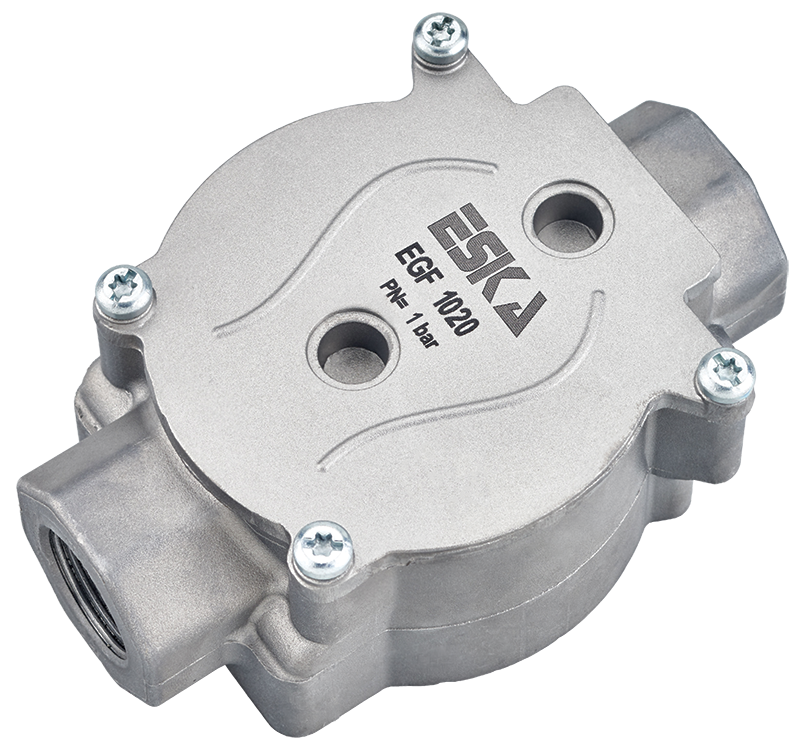

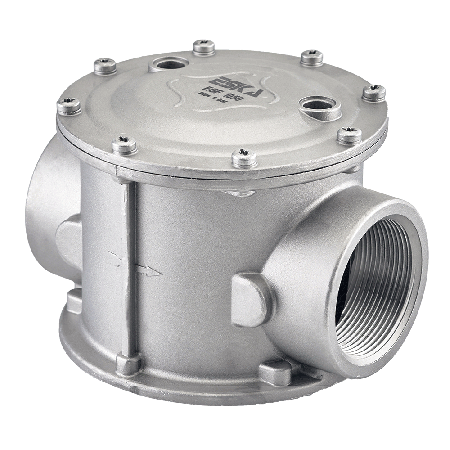

EGF model gas filters separates the dust particles carried by the gas or very small particles spread within the gas (for example: dust and rust), holds these and protects the burner, gas counter and adjustment devices which may possibly be damaged. Dust, woodchips, smut and other physical substances and dirt in the gas are held by the fiber. When the dust tank capacity is exceeded or a very high pressure difference effected, the filter loses its filter protection function. The Filters are resistant against the mechanical and thermal stress that occur under operational conditions. The device must be kept away from rain and water as much as possible.

High performing EGF filters are a popular choice for gas train manufacturers

Can be used for Non Corrosive Gasses in burner,/furnace applications

Approved as per international standards, the EGF series offers superior performance

| Medium | Non‐corrosive gases such as Natural Gas (Methane), LPG, Town Gas, Air, etc… |

| Presure Class | PN1 |

| Connection or Port Size | 1/2”, 3/4”, 1”, 11/4”, 11/2”, 2” Threaded (Female) and DN65, DN80 ,DN100 Flanged |

| Filter | Pore dimension as standard 50 micron (10-20 microns upon request) |

| Ambient Temperature | ‐20°C up to 60°C |

| Pressure test connection | ¼" Threaded Female |

| Assembly | Vertical and Horizontal Position |

| Material Standard | Aluminum-EN 1706 /Rubber-EN 549 |

| Medium | Non‐corrosive gases such as Natural Gas (Methane), LPG, Town Gas, Air, etc… |

| Presure Class | PN1 |

| Connection or Port Size | 1/2”, 3/4”, 1”, 11/4”, 11/2”, 2” Threaded (Female) and DN65, DN80 ,DN100 Flanged |

| Filter | Pore dimension as standard 50 micron (10-20 microns upon request) |

| Ambient Temperature | ‐20°C up to 60°C |

| Pressure test connection | ¼" Threaded Female |

| Assembly | Vertical and Horizontal Position |

| Material Standard | Aluminum-EN 1706 /Rubber-EN 549 |

© 2025 All Rights Reserved by Rm Supplier LLP